Validation / Qualification / Testing

Our Capabilities

- Author and execution of various Testing Protocol's for Validation and Qualification of systems and equipment for wide range of industries and utilities

- Development of documentation to satisfy Regulatory Requirements related to Validation and Qualification

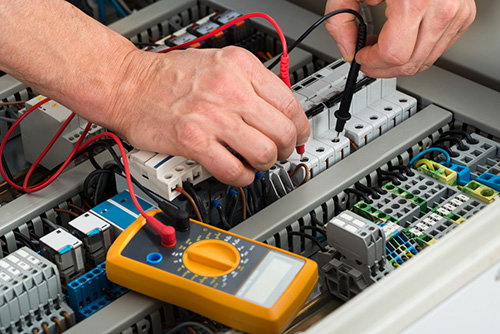

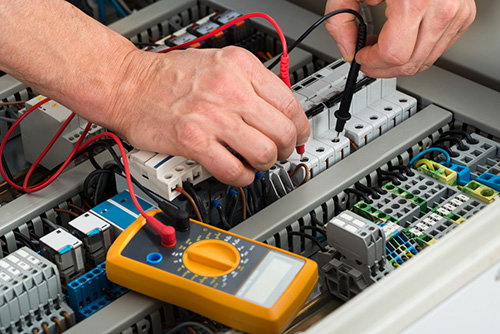

- Execution of hands-on field testing of entire processes/systems. Electrical I/O loop and motor testing, system piping and equipment survey and verification of proper installation

- Functional testing of installed equipment and systems

- Start-up and Commissioning of new and modified processes and equipment

- Factory Acceptance Testing to field verify that new equipment meets client requirements prior to shipment

- Site Acceptance Testing to field verify operation of equipment after installation on-site

Key Validation Services

- Equipment Installation Qualification (IQ)

- Equipment Operational Qualification (OQ)

- Control System Installation Qualification (IQ)

- Control System Installation Qualification (OQ)

- Process Qualification (PQ)

- Validation Final Report

- Startup & Test Procedures

- Protocol Execution

- Standard Operating Procedures

- Operations Manuals

- Operator Training

- Automation Validation

- Vendor Audits & Inspections

- Testing Standards Development

- Testing Procedure

- Design Review & Comment

- Field Testing

- Vendor Coordination

- Construction Coordination

- Analog Loop Testing

- Digital Loop Testing

- Instrument Calibration

- Control Schematic Checkout

- Component & System Functional Testing

- Integrated System Testing

- Control Logic Testing

- Equipment Problem Troubleshooting

- Construction Completion Records

- Operational Support

- Factory Acceptance Testing

- Medium & High Voltage Switchgear Breakers Testing

Copyright © MMXVIII. All rights reserved.